Maximizing Load Capacity: A Guide to Optimizing Fastening Techniques

When it comes to fastening, optimizing load capacity is crucial for ensuring the structural integrity and safety of various applications. Whether it's in construction, manufacturing, or engineering, understanding how to maximize load capacity through effective fastening techniques is essential. In this guide, we will delve into the key strategies and best practices for optimizing the load capacity of fastening, providing valuable insights for professionals in the industry.

Understanding Load Capacity

Before delving into the optimization techniques, it's important to have a clear understanding of what load capacity entails. Load capacity refers to the maximum amount of weight or force that a fastening system can withstand without failing. This is a critical factor in ensuring the stability and reliability of structures, machinery, and equipment.

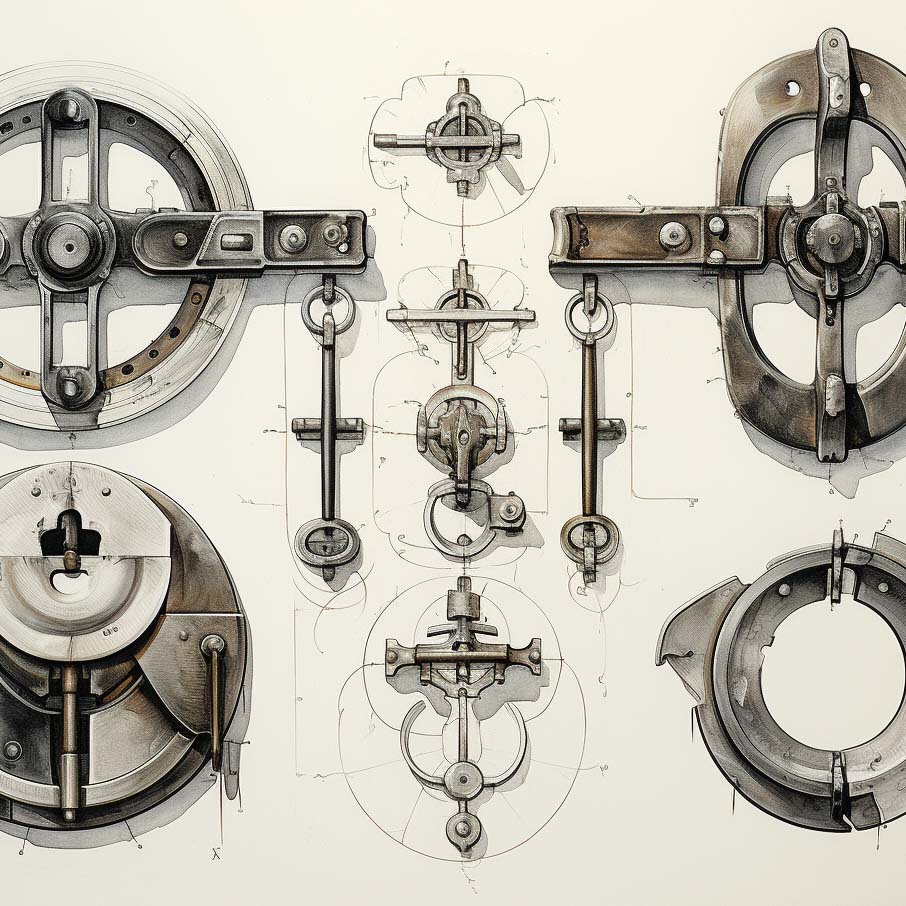

Selecting the Right Fastening Method

The first step in optimizing load capacity is to select the most suitable fastening method for the specific application. Whether it's bolts, screws, rivets, or adhesives, each fastening method has its own unique load capacity characteristics. Factors such as material strength, thread type, and installation torque play a significant role in determining the load capacity of the fastening system.

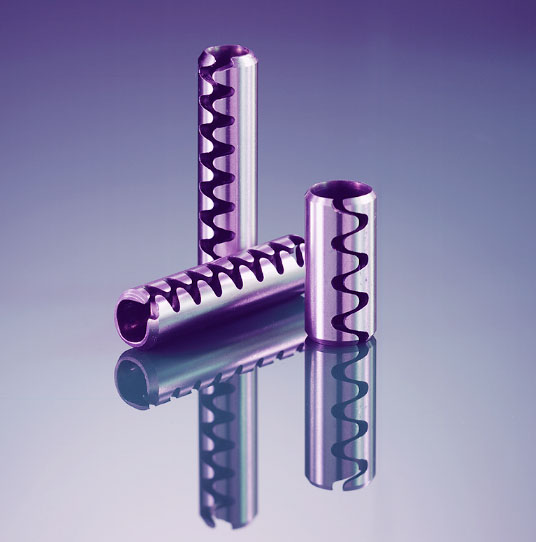

Utilizing High-Quality Fasteners

Investing in high-quality fasteners is paramount for maximizing load capacity. Inferior or substandard fasteners are more prone to failure under heavy loads, compromising the overall structural integrity. By opting for high-quality fasteners that meet industry standards and specifications, professionals can significantly enhance the load capacity of their fastening systems.

Proper Installation Techniques

Proper installation techniques are crucial for optimizing load capacity. This includes ensuring accurate torque values, proper alignment, and adequate tightening procedures. Over-tightening or under-tightening fasteners can lead to reduced load capacity and potential failure. Following manufacturer guidelines and industry best practices for installation is essential for achieving optimal load capacity.

Consideration of Environmental Factors

Environmental factors such as temperature variations, moisture, and corrosion can significantly impact the load capacity of fastening systems. Professionals should consider these factors when selecting fasteners and implementing fastening techniques. Utilizing corrosion-resistant materials, protective coatings, and proper sealing methods can help mitigate the impact of environmental factors on load capacity.

Regular Maintenance and Inspections

Regular maintenance and inspections are essential for ensuring the long-term load capacity of fastening systems. Over time, fasteners can experience wear, fatigue, and degradation, which can compromise their load capacity. Implementing a proactive maintenance schedule and conducting thorough inspections can help identify potential issues and prevent load capacity degradation.

Optimizing the load capacity of fastening is a critical aspect of ensuring the safety and reliability of various applications. By understanding the key strategies such as selecting the right fastening method, utilizing high-quality fasteners, proper installation techniques, considering environmental factors, and implementing regular maintenance, professionals can effectively maximize the load capacity of their fastening systems. This comprehensive approach not only enhances the performance of structures and equipment but also contributes to overall safety and longevity.