How to reduce the risk of failure during the process of raw material restructuring?

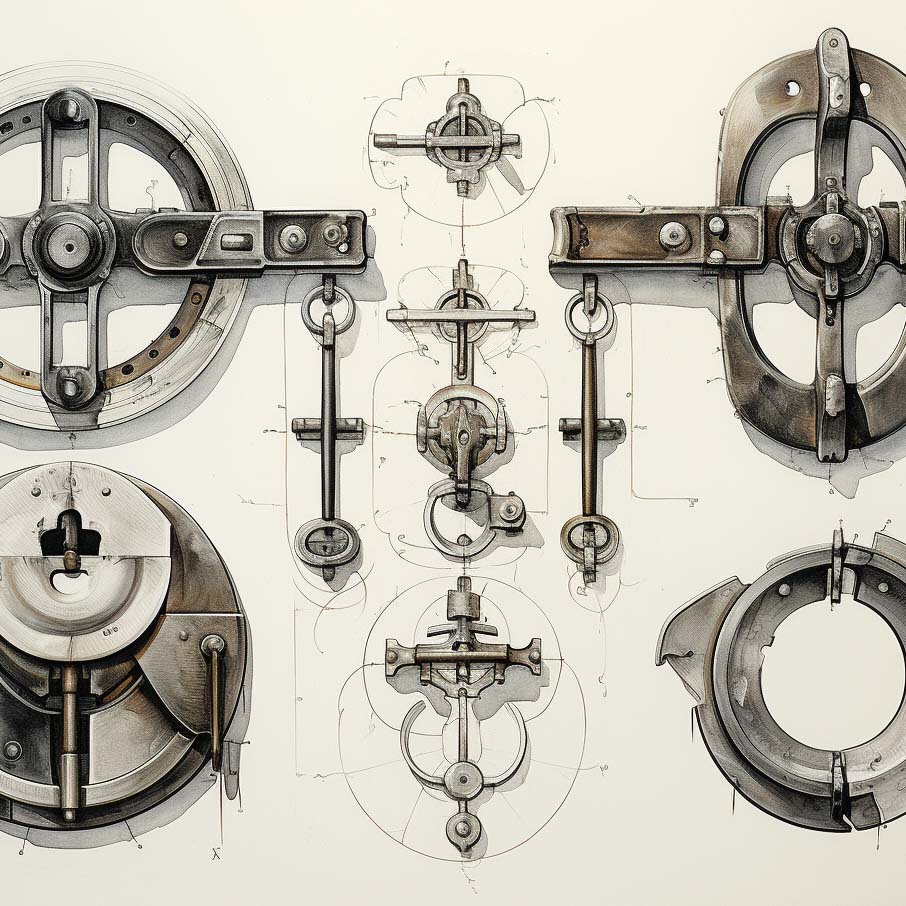

Today we are going to discuss the potential failure modes and countermeasures during the process of raw material restructuring. The raw material modification of fasteners is the first process in fastener production, which includes six major steps: material acceptance, annealing, pickling, phosphating, saponification, and drawing. In this process, there is a potential risk of failure in the pickling, phosphating, saponification, and drawing processes.

In the process of fastener raw material transformation, the key to reducing the risk of potential failure is to implement effective quality control and risk management measures. The following are potential failure modes and corresponding countermeasures for pickling, phosphating, saponification and wire drawing:

- Pickling:

- Potential failure modes: Problems such as uneven corrosion and substandard surface quality may occur during the pickling process.

- Countermeasures: Ensure that the concentration, temperature and processing time of the pickling solution meet the specification requirements, and regularly check the equipment status and pickling effect to ensure consistent pickling quality.

- Phosphating:

- Potential failure modes: Problems such as insufficient adhesion of the phosphate layer and uneven thickness of the phosphate layer may lead to poor coating quality.

- Countermeasures: Strictly control the composition and process parameters of the phosphating solution, ensure that the surface pretreatment and phosphating process meets standards, and regularly detect the thickness and adhesion of the phosphating layer.

- Saponification:

- Potential failure modes: Problems such as incomplete cleaning and residual contamination may occur during the saponification process, which will affect the adhesion and quality of subsequent coatings.

- Countermeasures: Ensure the proportion and temperature of the saponification solution are appropriate, strictly control the cleaning process, and use appropriate cleaning agents and equipment to ensure surface cleanliness and quality.

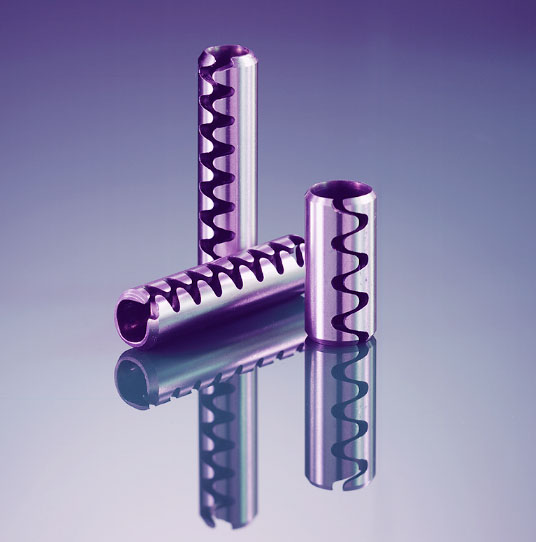

- Drawing:

- Potential failure modes: Strain, surface defects and other problems may occur during the wire drawing process, affecting the mechanical properties and appearance quality of the fasteners.

- Countermeasures: Strictly control the drawing process parameters, ensure appropriate drawing speed, tension and cooling conditions, and regularly detect the material properties and surface quality after drawing.

In addition to the above measures, establishing a sound quality management system, strengthening employee training and awareness education, regular equipment maintenance and calibration, and comprehensive testing of raw materials and finished products are all important means to reduce the risk of failure.

Our Website: https://www.fastoscrews.com/, feel free to contact us.