A Detailed Comparison of Hexagon Socket Bolts DIN6912 and DIN7984

In the field of industry and manufacturing, bolts are indispensable connectors. Especially in the precise and compact assembly environment, thin hexagon socket bolts are favored for their unique advantages. Among them, DIN6912 and DIN7984 are two common thin hexagon socket bolts. Although they have similar functions, they have significant differences in design and application.

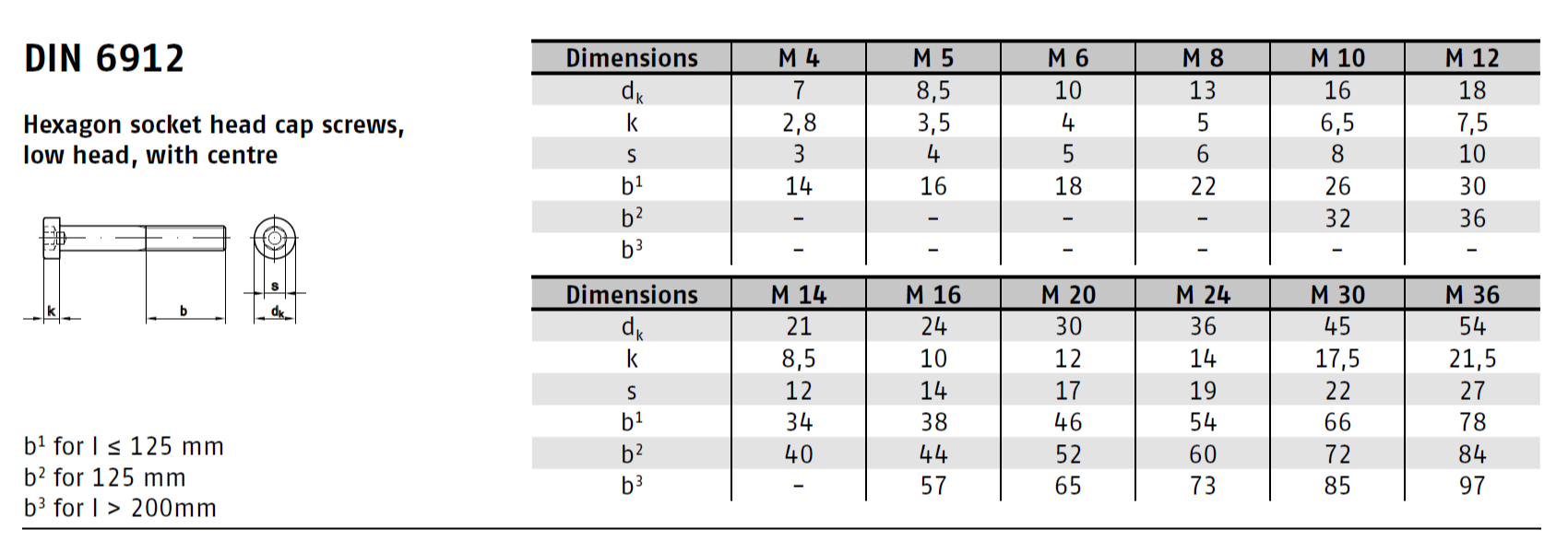

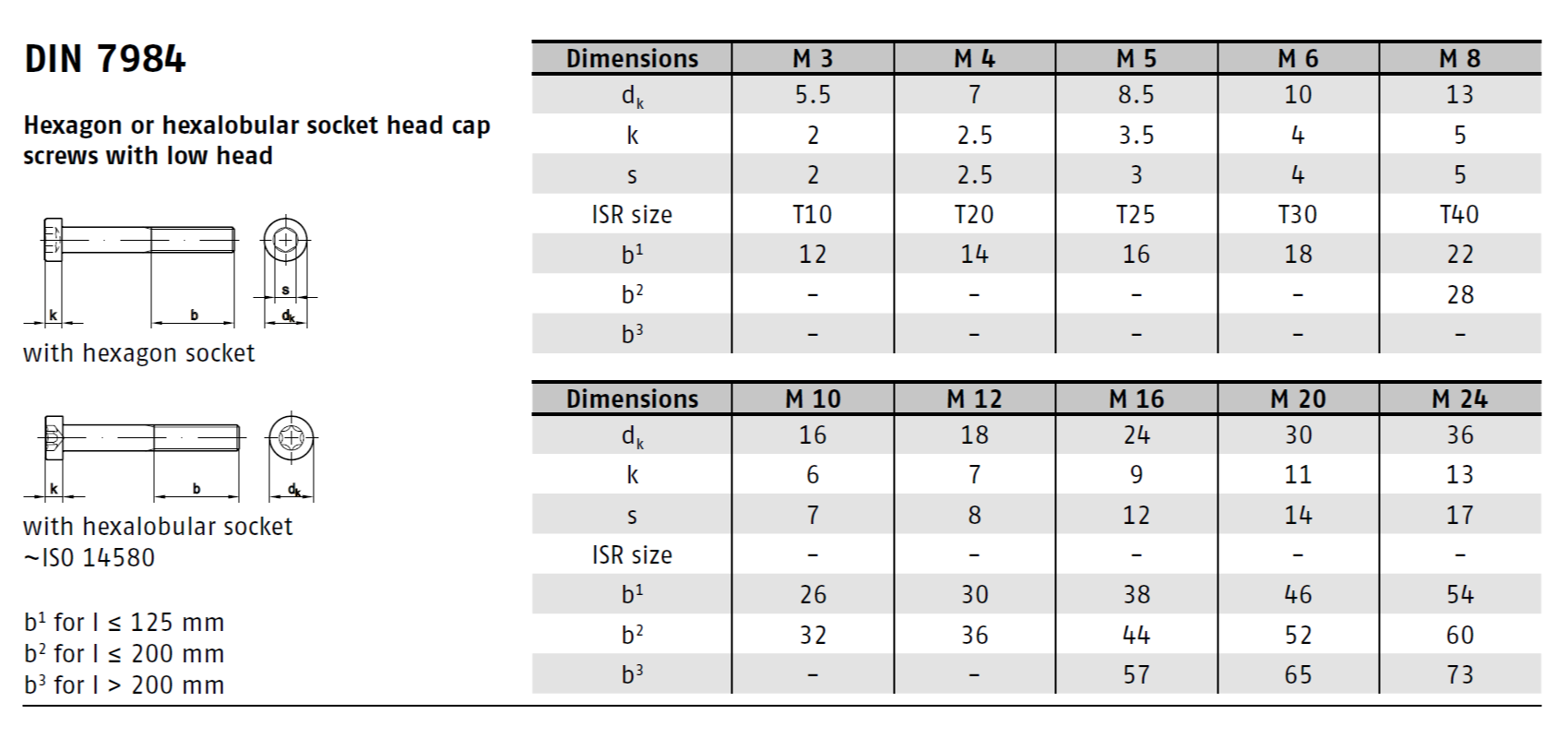

First of all, from the appearance, the most obvious difference between DIN6912 and DIN7984 is the design of the head. DIN6912, also known as thin hexagon socket cylindrical head screw with guide hole, is characterized by a guide hole (or positioning hole) in the center of the head. This guide hole not only increases the beauty of the bolt, but more importantly, it facilitates the installation and removal process. In contrast, DIN7984 does not have such a guide hole design, and its head is more concise.

Next, let's take a look at the size difference between the two bolts. Although the head diameters of the two are basically the same, they differ in the two key dimensions of the opposite side s of the hexagon socket and the head thickness k. Specifically, due to the guide hole, the head thickness of DIN6912 may be relatively thin to accommodate the existence of the guide hole. Since DIN7984 has no guide hole, its head thickness may be thicker, thus ensuring sufficient strength and stability.

This difference in size not only affects the visual effect of the bolt, but more importantly, it affects the load-bearing capacity and usage scenarios of the bolt. Since DIN6912 has a thinner head and its load-bearing capacity is relatively low, it is more suitable for occasions that do not require high load-bearing capacity but require compact space. DIN7984 has a higher load-bearing capacity due to its thicker head and is suitable for scenarios with higher strength requirements.

In addition to the differences in appearance and size, the tools used in the installation and removal process of DIN6912 and DIN7984 are also different. Since DIN6912 has a guide hole, a special hexagonal wrench is required for installation and removal. This wrench usually has a locating pin that matches the guide hole, which can ensure the precise alignment between the wrench and the bolt, thereby improving the efficiency and accuracy of installation and removal. DIN7984 can be operated with an ordinary hexagonal wrench.

In terms of material and performance, both DIN6912 and DIN7984 offer a variety of options. They can be made of materials such as carbon steel or stainless steel to meet the use requirements in different scenarios. Among carbon steel bolts, they usually have different strength grades such as CL8.8/10.9. However, it should be noted that due to the thin head of DIN6912, its load-bearing capacity may be limited to a certain extent, so it is necessary to weigh it according to the actual situation when choosing.

Finally, in terms of environmental protection and sustainability, both DIN6912 and DIN7984 provide a variety of environmentally friendly coating options, such as zinc-nickel coating and thick film passivation galvanizing. These coatings not only have good corrosion resistance, but also do not contain harmful substances, which meets the requirements of modern environmental protection and sustainable development.

In summary, as two common thin hexagon socket bolts, DIN6912 and DIN7984 have significant differences in appearance, size, installation tools, materials and performance. When choosing, it is necessary to weigh and choose according to the actual usage scenarios and needs.

Our Website: shttps://www.fastoscrews.com/, feel free to contact us.